Are you sure?

Are you sure? If you change your country now, any items you have added to your quote will disappear.

Your location

Please set your location to see relevant stock levels. Freight costs and taxes will be calculated once you log in.

Note: changing your location will empty your cart.

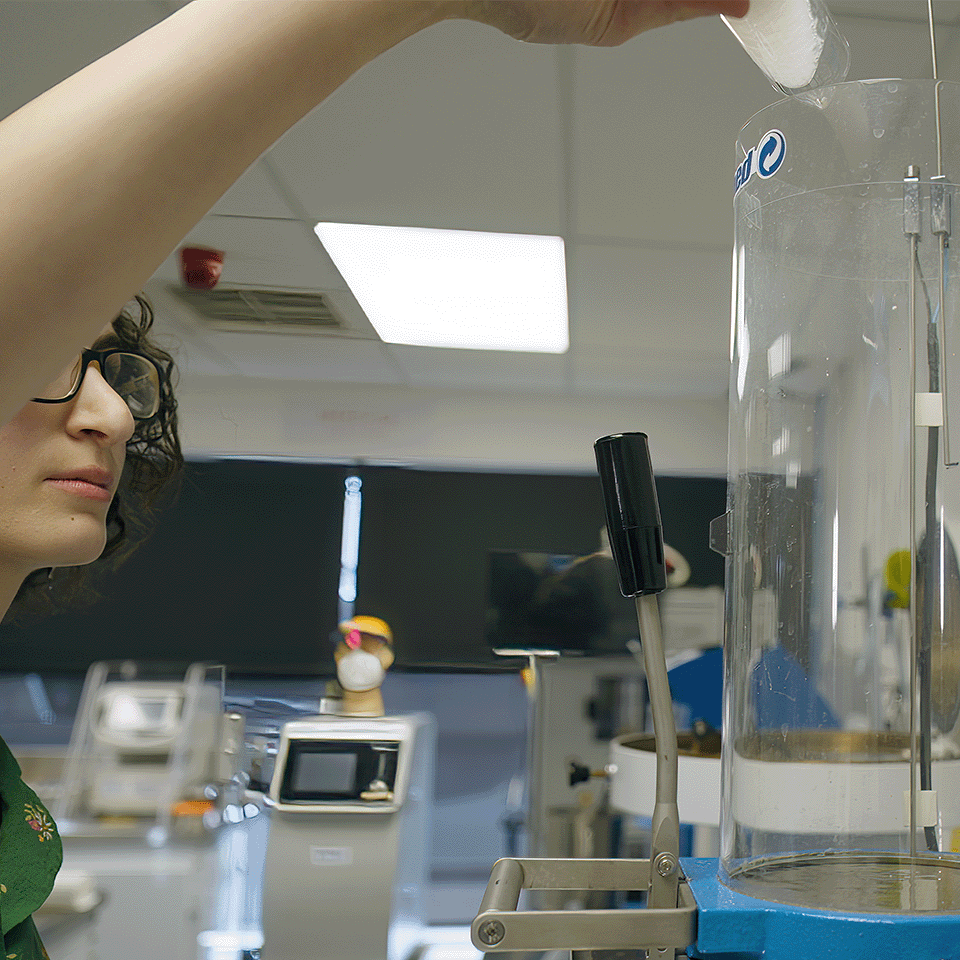

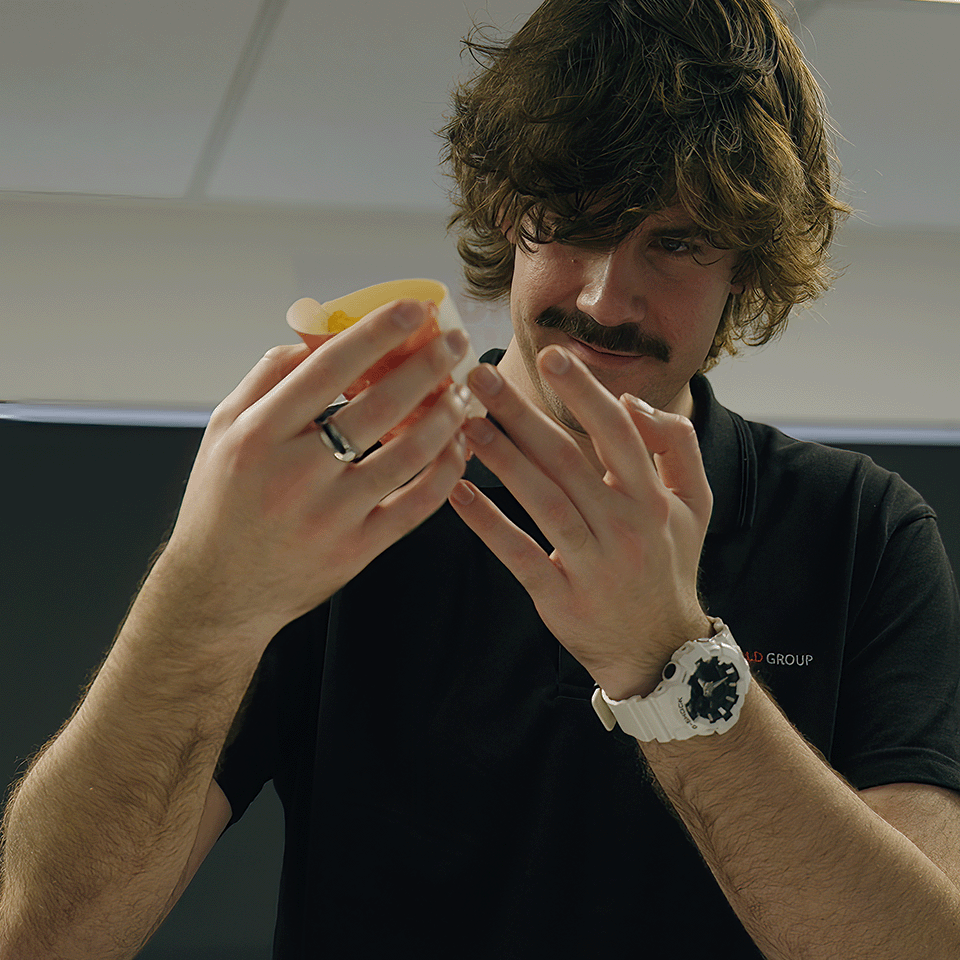

We understand that every aspect of your business is unique. That’s why we created LaunchPad, an innovation hub run by our team of industrial and graphic designers, research and development specialists and project management experts. The incorporated R&D lab enables leading-edge product development for complex problems and provides customers with fit-for-purpose solutions that meet market demands.

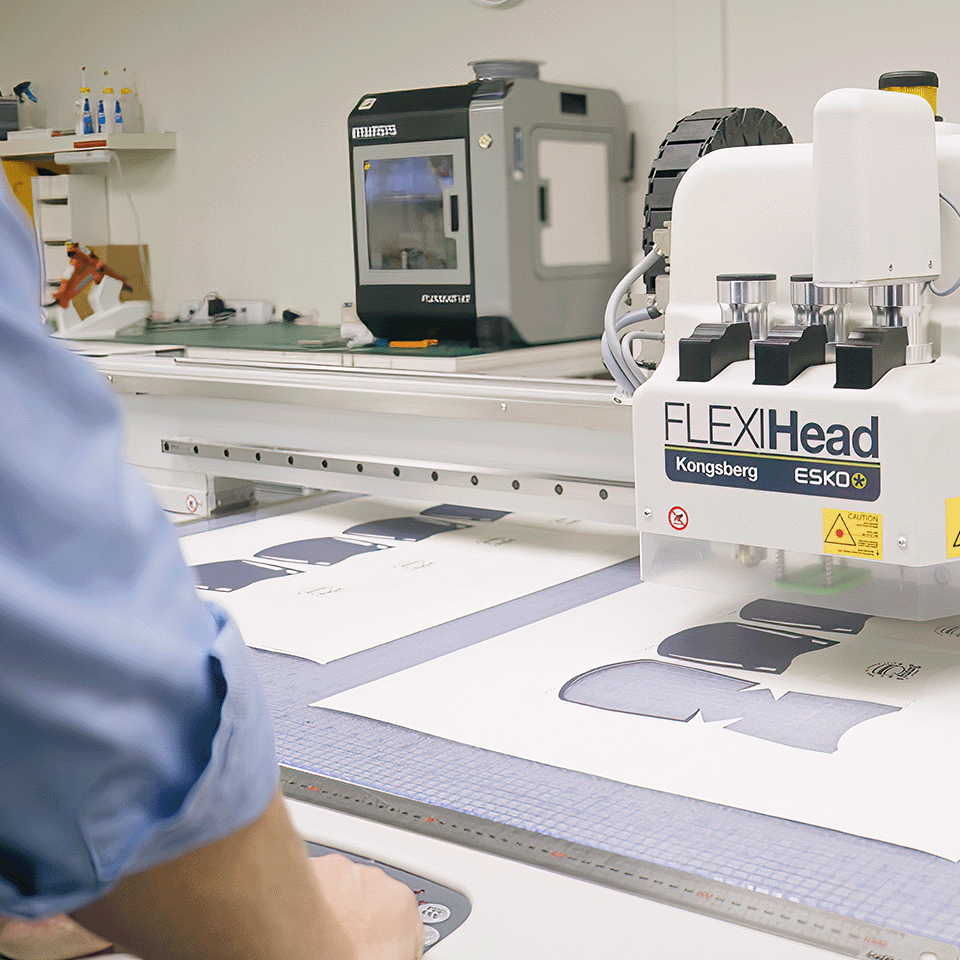

DESIGN

In-house designers focus on both product and graphic design, addressing the aesthetic, functional, and prototyping aspects of packaging through collaboration and partnerships.

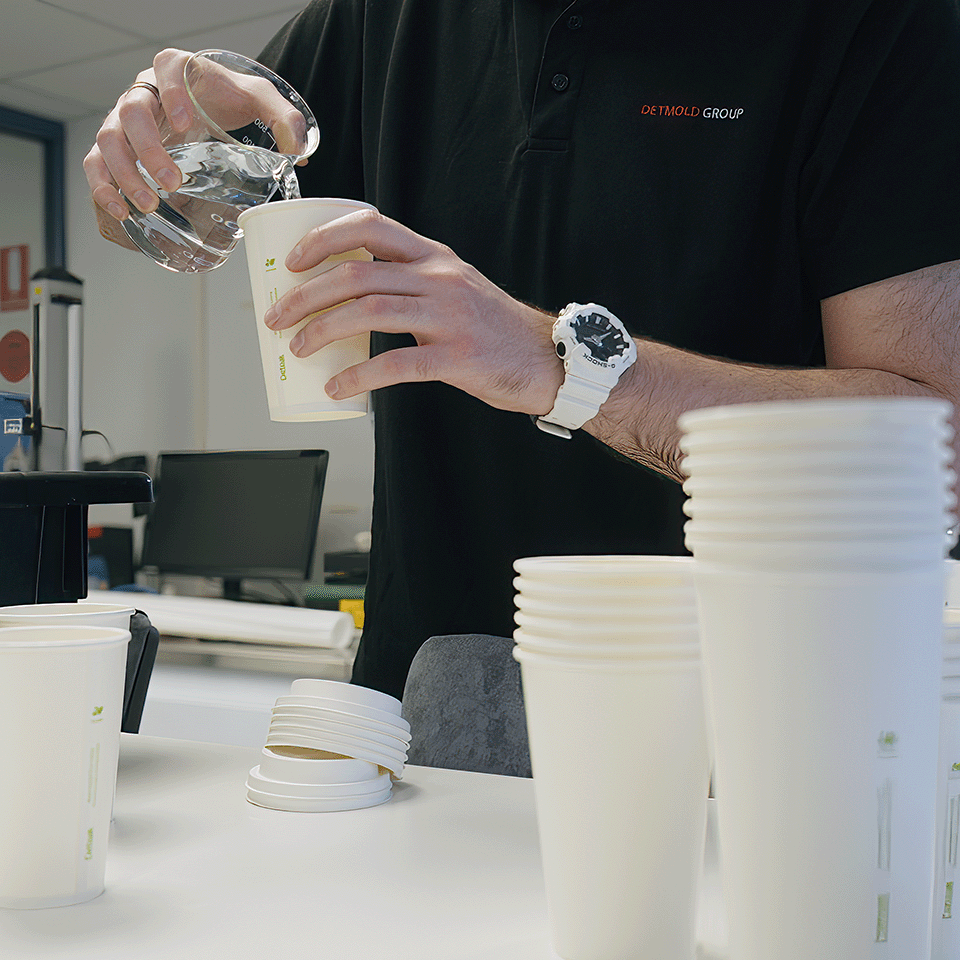

DEVELOP

We manage the project pipeline, ensuring all initiatives align with legislative, performance and sustainability targets.

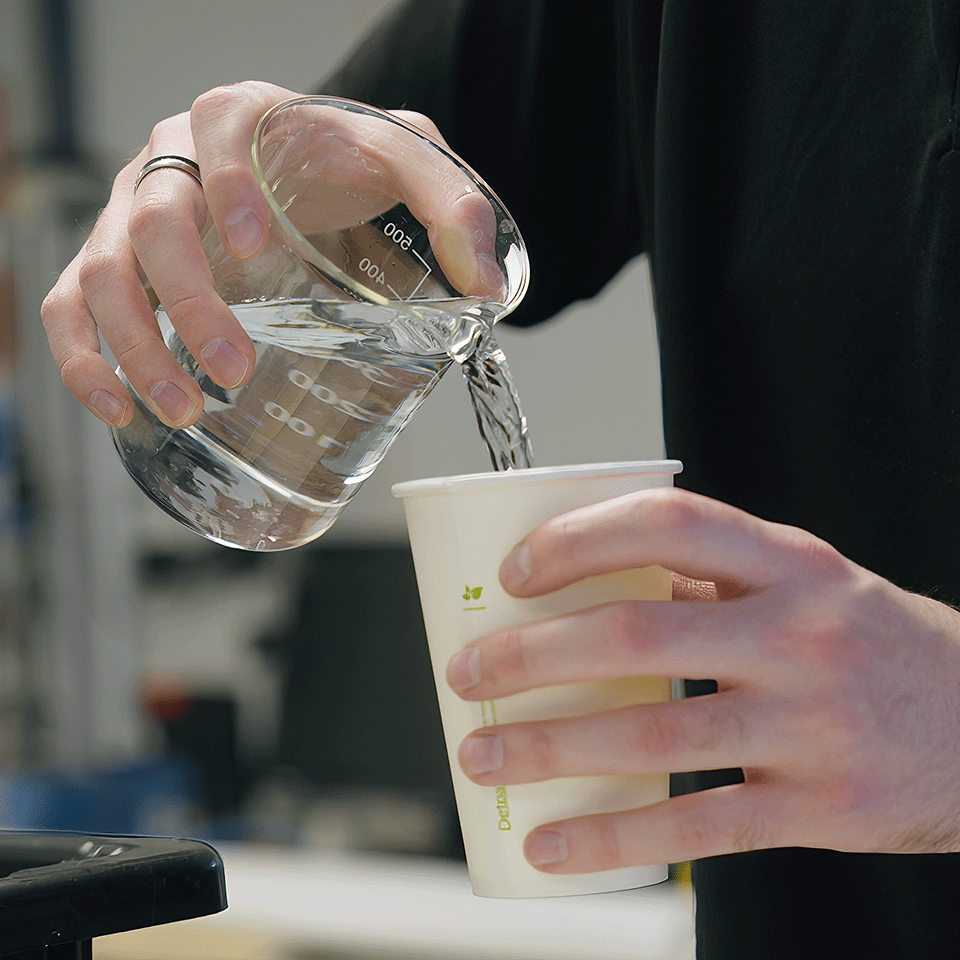

DISCOVER

R&D specialists, including a dedicated LaunchPad lab team, work closely with global teams, facilities and technologies to discover new materials and processes that meet market demands and ensure you’re using the latest sustainable products.